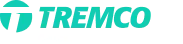

Cold Fluid-Applied Waterproofing

TREMproof® cold fluid-applied waterproofing systems provide long-term protection in both vertical and horizontal applications including backfilled walls, retaining walls, split-slab, planters and submerged conditions. They are fully compatible with a complete line of primers, drainage mats, protection courses, reinforcing materials – in addition to Tremco tapes, detailing sealants, waterstops and more.

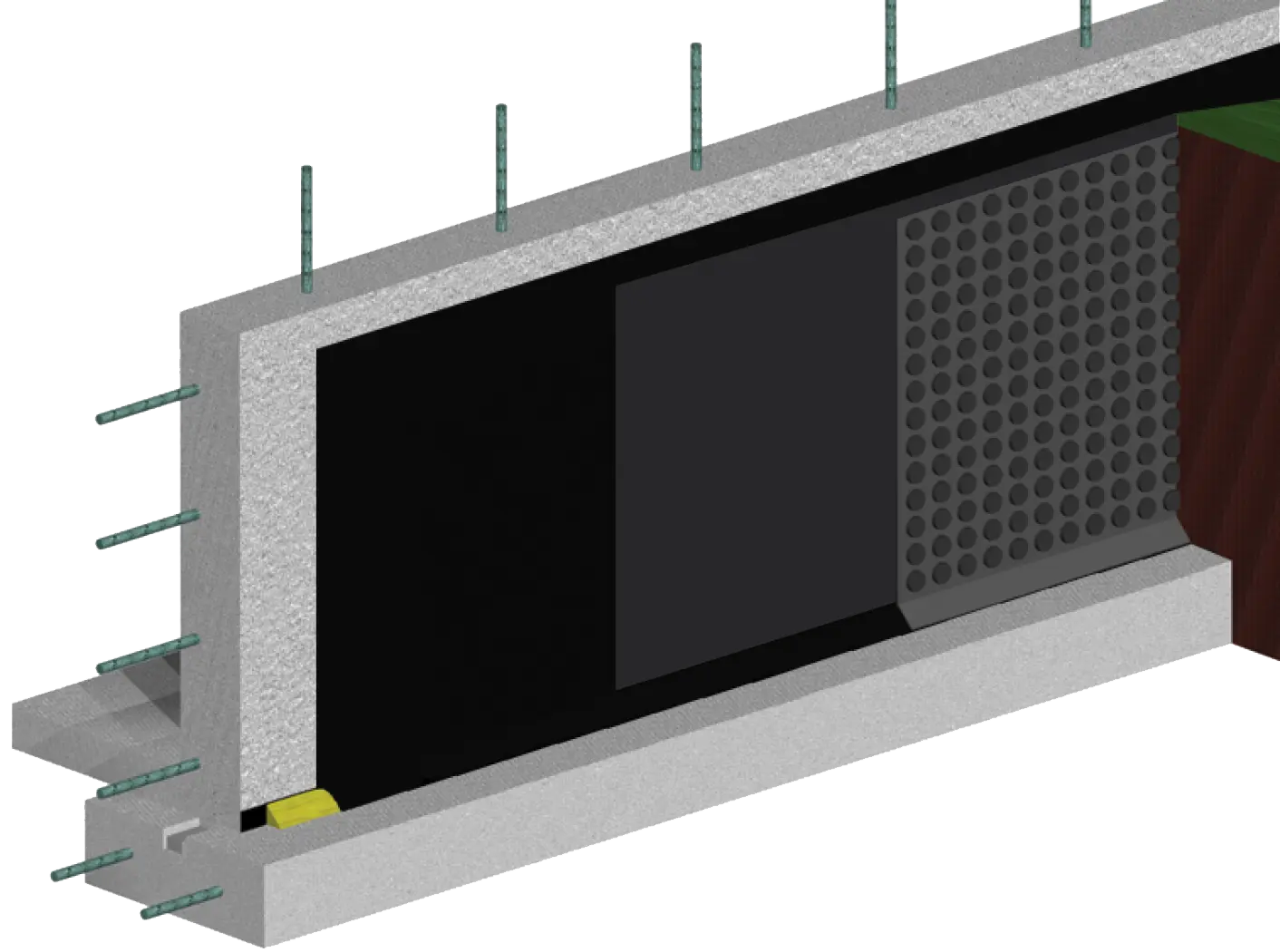

Drainage

Drainage

Protection Courses

Protection Courses

Cold Fluid-Applied Waterproofing Membranes

Cold Fluid-Applied Waterproofing Membranes

Dymonic® 100

Dymonic® 100

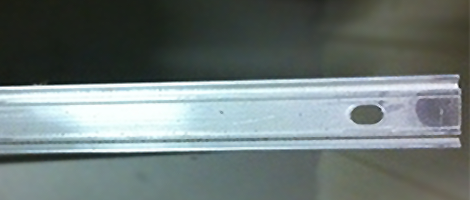

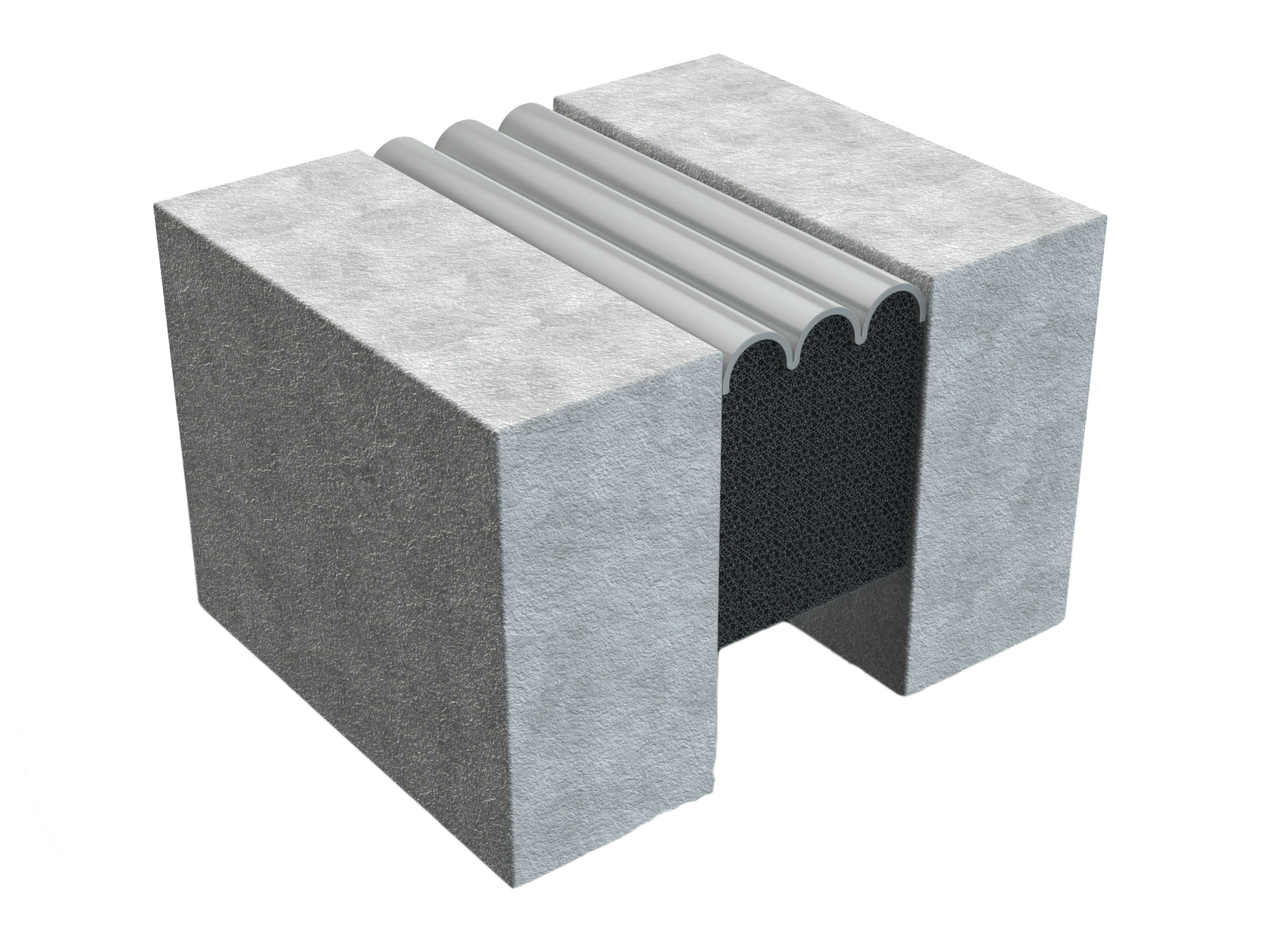

Paraseal® Paraterm Bar™

Paraseal® Paraterm Bar™

TREMproof® 250GC

TREMproof® 250GC

Willseal® 250

Willseal® 250