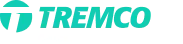

Balcony & Light Pedestrian Traffic Systems

Vulkem® pedestrian traffic systems are designed for light-to-medium pedestrian traffic, in areas like balconies, walkways and terraces. Find your perfect system with single- and two-component systems, plus quick-cure, UV-stable and low-VOC options. Additionally, you can maximize your project’s aesthetic with systems that incorporate decorative flakes or quartz.

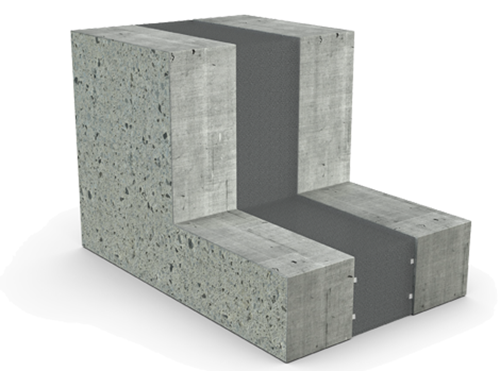

Dymonic® 100

Dymonic® 100

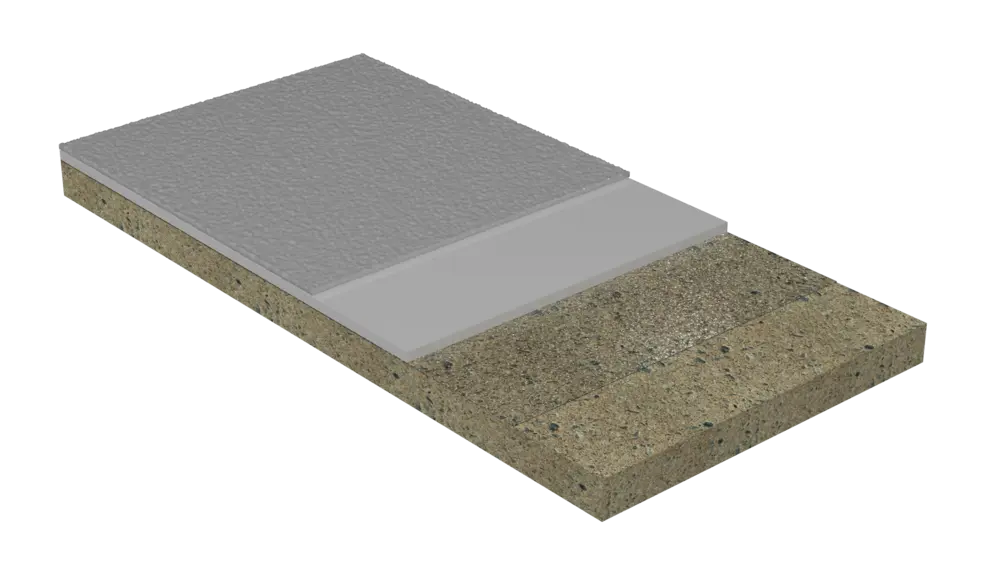

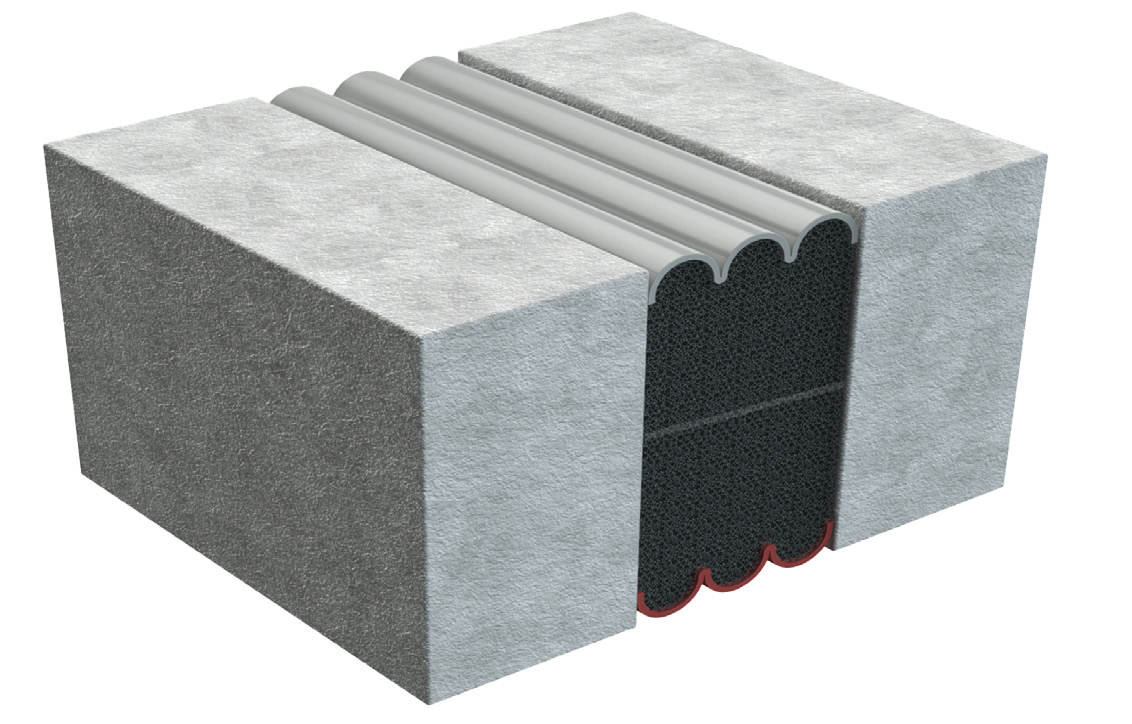

Willseal® 250

Willseal® 250

Willseal® Color Coreseal H

Willseal® Color Coreseal H

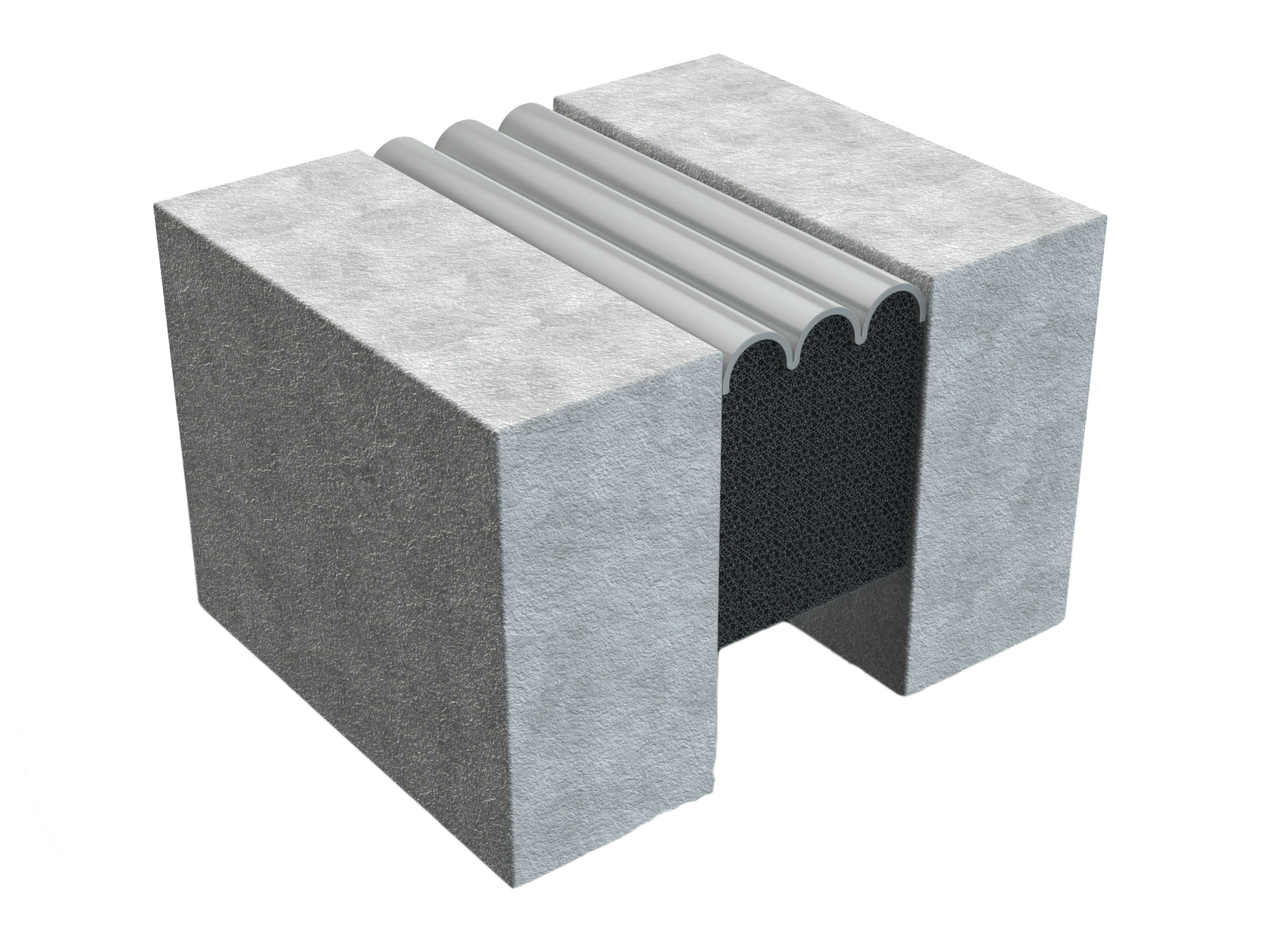

Willseal® Coreseal

Willseal® Coreseal

Willseal® FR-H

Willseal® FR-H