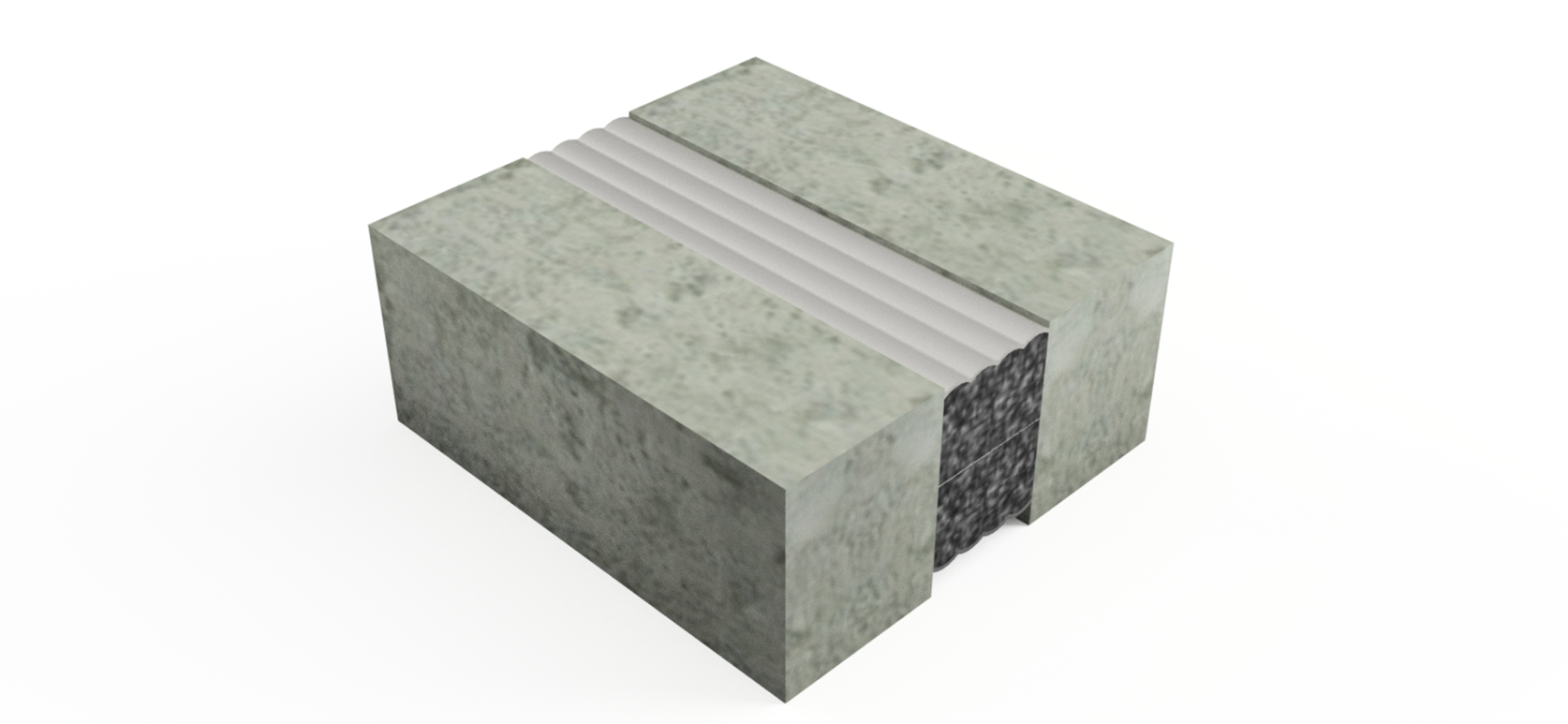

Willseal® FR/SAF-V is a fire-rated, pre-compressed, watertight, UV stable foam, with an integral smoke barrier within the foam body, sound-attenuating expansion joint with a pre-cured, factory-applied pick-resistant sealant applied to the face. FR-V is comprised of a fire-retardant impregnated foam designed to be used in vertical expansion joints by itself, without the addition of an intumescent sealant on the foam surface.

Fire-rated expansion joint sealants are specially designed to provide fire protection in buildings where there is a potential for the spread of fire through openings in walls or floors. They are used to fill gaps or spaces between building components, such as walls, floors, and ceilings, that may expand or contract due to temperature changes. In the North American market, “fire-rated expansion joints” generally means the system has been tested to and passed UL 2079 testing. The UL 2079 test provides prescriptive systems that include more than just the expansion joint, including: what the sidewalls are made of; sidewall depth; fire endurance duration; expansion joint movement capability; thermal transfer evaluation; and other additional properties. Like other passive fire protection products, fire-rated expansion joints are only considered compliant if they are properly installed into approved systems.

Fire-rated expansion joints rely on three primary properties to pass the industry standard UL 2079 testing, they are:

Fire-rated expansion joints have been put through the rigors of whatever test standard they reference back to and include mandatory substrate, accessory, and other considerations to be a compliant aspect of an approved system. Expansion joints that are “non-FR” would by nature of being precompressed retain strong fire-resistant properties but are not held to the stringent requirements associated with fire-rated assemblies, that being said many “non-fire-rated” expansion joints would still generally have some fire-resistant capabilities.

No, there are different types of fire-rated expansion joint sealants available on the market. They differ in composition, performance characteristics, and certifications. It is important to choose a sealant that meets all necessary requirements for your specific project.

A pre-compressed foam expansion joint is a type of fire-rated expansion joint sealant that consists of a foam core compressed between two layers of fire-resistant material. When installed, the foam expands to fill the gap and provide fire protection.

The size and type of pre-compressed foam expansion joint needed for your project will depend on several factors such as the width and depth of the gap, expected movement between building components, and required fire rating. It is best to consult with a professional to determine the most suitable option for your specific project.

While pre-compressed foam expansion joints are suitable for a wide range of construction applications, it is important to check building codes and regulations in your area. Some projects may require specific fire ratings or materials that differ from standard pre-compressed foam expansion joints.

The lifespan of fire-rated expansion joint sealants can vary depending on factors such as exposure to weather elements and movement between building components. It is recommended to regularly inspect and maintain the sealants, and replace them when necessary to ensure continued fire protection.

It is best to hire a professional contractor experienced in installing fire-rated expansion joint sealants to ensure proper installation and compliance with building codes and regulations. Improper installation can result in a non-compliant system; compromise the effectiveness of the sealant; and put the building at risk for fire spread.

In addition to providing fire protection, fire-rated expansion joint sealants also help reduce noise, prevent water and air infiltration, and maintain structural integrity by accommodating movement between building components with the benefit of using non-invasive anchoring. They can also improve the overall aesthetic of a building by filling gaps and creating clean, uniform joints. So, it is essential to use them in appropriate places.

Mineral wool expansion joints are made from fibrous materials that can withstand high temperatures and resist the spread of flames. Unlike pre-compressed foam expansion joints, mineral wool expansion joints do not expand; instead, they provide a dense, insulating barrier that offers excellent fire resistance and soundproofing. While pre-compressed foam joints allow for more flexibility and movement, mineral wool may be better suited for applications requiring high thermal and sound insulation.

Both mineral wool and pre-compressed foam expansion joints are fire-rated and designed to prevent the spread of fire. The choice between the two should be based on specific project requirements, including desired fire ratings and thermal insulation levels.

In some construction projects, it may be advantageous to use both mineral wool and pre-compressed foam expansion joints to leverage the strengths of each material. For instance, mineral wool can provide enhanced fire and sound insulation, while pre-compressed foam can provide environmental sealing properties and sustain pedestrian and vehicular traffic and is often used in applications with depth restrictions that would prohibit mineral wool seals.

The installation process for mineral wool expansion joints typically involves cutting and fitting the wool into spaces that require fireproofing, often needing precise handling to maintain its effectiveness. Pre-compressed foam expansion joints, on the other hand, are installed in their compressed state and allowed to expand into the gap. Each material may require different skills and expertise for proper installation, making it important to consult with professionals familiar with each type of joint.